Introduction

In the construction industry, whether working on massive skyscrapers or modest residential renovations, accurate estimation is an essential cornerstone for project success. This is especially true for small-scale projects, where budgets are tight, timelines short, and resource margins slim. Even minor miscalculations can cause cascading problems such as cost overruns, schedule delays, resource shortages, and quality compromises. For these projects, an accurate, well-researched estimate is not just a useful tool but a necessity.

This article delves into why accurate estimation matters profoundly for small-scale projects, how it affects all construction phases, and what best practices contractors and project managers can adopt. We will also examine real-world examples demonstrating the transformative power of precise estimation, answering frequently asked questions, and providing actionable tips to boost estimation accuracy.

Understanding Construction Estimation: More Than Just Numbers

Construction estimation systematically forecasts all costs involved in completing a project from start to finish. It includes everything from raw materials and labor wages to equipment, permits, subcontractor fees, and unexpected contingencies.

For small projects, the challenge is that the estimation process must balance detail with efficiency — overly complex processes slow down decision-making, while excessively simplistic estimates risk significant error. The key components include:

- Detailed quantity take-offs (QTO): Precise measurement of material quantities to minimize waste and ensure procurement accuracy.

- Labor cost estimation: Calculating the number of man-hours required and applying appropriate wage rates.

- Equipment and tool costs: Considering rental fees, maintenance, and depreciation where applicable.

- Subcontractor and supplier quotes: Gathering competitive bids to reflect market rates.

- Soft costs: Permit fees, design and engineering fees, insurance, and overheads.

- Contingency allowances: Financial buffers to handle uncertainties like weather delays or design changes.

Estimation is both an art and a science: it requires technical know-how, experience, and a deep understanding of local market conditions.

Why Accurate Estimation is Even More Crucial for Small-Scale Projects

1. Tight Budget Constraints Leave No Room for Error

Unlike large projects with sizable budgets and contingency reserves, small projects often have fixed funding limits. A 5% overrun on a multimillion-dollar project might be manageable, but the same percentage on a $100,000 small-scale project could exhaust the entire contingency fund and stall work.

Example: A small home renovation with a $50,000 budget experiencing a $2,500 cost overrun could force scope cuts or require emergency financing.

2. Limited Resources Demand Precise Scheduling

Small projects typically run on compressed timelines with limited labor and material resources. Accurate estimation helps create realistic work schedules that avoid costly downtime or rushed work.

Impact: Overestimating material needs may lead to idle inventory and cash flow issues, while underestimating can cause procurement delays and idle labor.

3. Higher Relative Impact of Risks

Risks such as price fluctuations, labor shortages, or unexpected site conditions have proportionally greater consequences on small projects.

- Case in point: A sudden 10% price increase in lumber can derail a small budget more severely than a large project with diversified resources.

4. Client Expectations and Reputation

Small-scale projects often involve individual homeowners or small businesses who expect clear communication, transparency, and minimal surprises. Accurate estimates build trust and protect the contractor’s reputation.

Common Challenges in Small-Scale Project Estimation

Understanding common pitfalls helps in avoiding them:

- Incomplete Scope Definition: Lack of clarity leads to assumptions and omissions, resulting in underestimated costs.

- Ignoring Soft Costs: Many small project estimators focus only on hard costs, forgetting permits, inspections, or site preparation fees.

- Poor Historical Data: Small contractors or new businesses may lack reliable past project data for reference.

- Market Volatility: Small projects often feel the brunt of sudden price shifts in materials or labor.

- Inadequate Contingency Planning: Overconfidence in estimates without risk buffers sets projects up for failure.

Step-by-Step Methodology for Accurate Estimation

Step 1: Define the Project Scope in Detail

Start with comprehensive project plans, drawings, and specifications. Engage clients and designers early to finalize exact requirements.

- Use checklists and work breakdown structures (WBS) to capture every task.

- Identify any optional or phased elements that may affect costs.

Step 2: Perform Precise Quantity Take-Offs (QTO)

Use digital tools or manual methods to calculate exact material quantities.

- Cross-check measurements from drawings

- Include waste factors for cutting or breakage

- Consider local supplier packaging units for procurement efficiency

Step 3: Source Multiple Vendor and Subcontractor Quotes

Obtain updated quotes to reflect current market prices.

- Compare pricing and lead times

- Negotiate bulk discounts where applicable

Step 4: Calculate Labor Costs Accurately

Estimate labor hours task by task.

- Factor in crew productivity and skill levels

- Include costs for supervision and support staff

Step 5: Account for Equipment and Tools

Consider ownership costs or rentals.

Add transportation and setup time for the machinery

Step 6: Add Soft Costs and Permits

Estimate inspections, permits, insurance, bonds, and project management fees.

Step 7: Incorporate Contingencies and Risk Allowances

Assess project risks and add 5-10% contingencies depending on complexity.

Document assumptions and risk factors

Step 8: Review and Refine Estimate

Validate estimates with project stakeholders and review against historical data.

Adjust for design changes or client feedback

Benefits of Accurate Estimation for Small Projects

Improved Budget Management

- Prevents cost overruns and maximises profitability

- Facilitates better cash flow planning and reduces financing needs

Enhanced Scheduling and Resource Allocation

- Reduces downtime by matching labor and materials with realistic timelines

- Minimizes procurement delays and project bottlenecks

Risk Mitigation

- Helps identify and plan for potential project risks early

- Allows for contingency funds that prevent project halts

Client Trust and Satisfaction

- Builds confidence through transparent, realistic project expectations

- Leads to better client relationships and repeat business

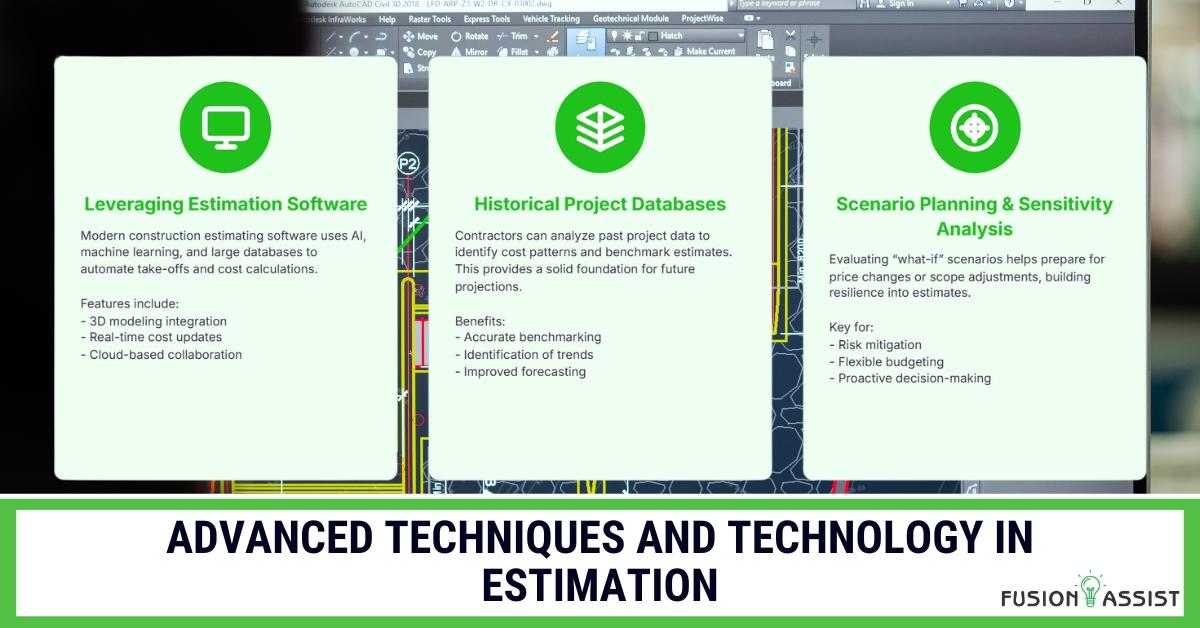

Advanced Techniques and Technology in Estimation

Leveraging Estimation Software

Modern construction estimating software uses AI, machine learning, and large databases to automate take-offs and cost calculations.

- Features like 3D modeling integration and real-time cost updates improve accuracy

- Cloud-based platforms enable collaboration among multiple stakeholders

Use of Historical Project Databases

Contractors can analyze past project data to identify cost patterns and benchmark estimates.

Scenario Planning and Sensitivity Analysis

Evaluating “what-if” scenarios helps prepare for price changes or scope adjustments.

Case Studies By Fusion Assist – Accurate Estimation in Small-Scale Projects

Case Study 1: Successful Retail Store Renovation in Chicago

Project Overview

A local boutique owner planned a 2,500 sq ft interior renovation to update the store before the holiday season. The project had a fixed budget and a strict deadline, making accurate estimation critical.

Initial Challenges

- Previous rough estimates had been off by nearly 20%, risking overspending.

- A tight timeline required precise scheduling to avoid missing the holiday sales window.

Estimation Process

- Detailed Scope Definition: The contractor conducted multiple walkthroughs with the client to clarify exact renovation requirements, including electrical upgrades and custom fixtures.

- Quantity Take-Off: Using digital software, the team precisely measured material quantities such as drywall, flooring, and paint.

- Vendor Quotes: The contractor sourced bids from five local suppliers to secure competitive pricing.

- Labor Estimation: Man-hours were estimated based on crew skill levels and previous similar projects.

- Contingency Planning: A 7% contingency allowance was added for potential design changes or unforeseen issues.

Outcomes

- The project was completed 15% under budget and two weeks ahead of schedule.

- The client praised transparent cost updates and realistic timelines.

- This success led to repeat business and referrals for the contractor.

Case Study 2: Custom Home Construction in Austin, Texas

Project Overview

A private homeowner commissioned a custom-built home with a moderate budget. Early estimates underestimated site preparation and permitting costs, leading to potential budget shortfalls.

Initial Challenges

- Site-specific conditions such as soil quality and drainage were not fully accounted for.

- Permit approvals required additional time and fees that were initially overlooked.

Estimation Process

- Comprehensive Site Survey: The estimator incorporated detailed soil testing and environmental assessments into the scope.

- Permit and Soft Cost Inclusion: The project plan included all local government fees, inspections, and insurance requirements.

- Labor and Material Cost Updates: Vendors reviewed prices regularly to adjust for market changes.

- Contingency Buffer: A 10% contingency was allocated due to uncertainties with site conditions.

Outcomes

- Unexpected costs of approximately $50,000 were avoided through early identification.

- The project secured permits on schedule, preventing delays.

- The homeowner expressed satisfaction with the transparent and proactive communication.

Case Study 3: Community Park Upgrade in Denver, Colorado

Project Overview

A city municipality tasked a contractor with upgrading a community park within a strict public budget of $500,000. Accuracy in estimation was vital to ensure the efficient use of public funds.

Initial Challenges

- The project included new playground equipment, landscaping, and lighting upgrades.

- Weather and seasonal factors posed risks for schedule delays.

Estimation Process

- Local Supplier Engagement: The team prioritized sourcing materials locally to reduce transportation costs and support community businesses.

- Risk Assessment: A risk register was developed to identify potential weather-related delays and budget impacts.

- Schedule and Budget Reviews: Weekly progress meetings were held to track expenditures against estimates.

- Detailed Labor and Equipment Costs: Hourly rates and machinery usage were carefully calculated to reflect actual work plans.

Outcomes

- The project was completed within $5,000 of the original estimate on a $500,000 budget.

- Early completion before peak season allowed immediate public use.

- The municipality lauded the project for its financial transparency and community impact.

Conclusion

Accurate estimation is critical for small—scale projects. The tight financial and time constraints typical of these projects magnify the consequences of any estimation errors. Contractors who invest in detailed scope definition, leverage technology, use historical data, and engage all stakeholders create realistic, reliable estimates that lead to smoother project execution, satisfied clients, and stronger profitability.

Embracing best practices in estimation is an investment that pays dividends through cost savings, risk mitigation, and enhanced reputation.

If you’re planning a small-scale construction project and want to ensure success through precise estimation, partner with professionals experienced in delivering accurate, detailed estimates. Contact us today to discover how our expertise and advanced tools can help you stay on budget and on schedule from start to finish.

Frequently Asked Questions (FAQs)

What differentiates an estimate from a bid?

An estimate forecasts project costs and is often flexible. A bid is a fixed-price offer to complete the project, usually based on the estimate.

How often should estimates be updated?

Estimates should be reviewed at every major project milestone, such as design changes, permit approvals, or market shifts.

Can small contractors benefit from advanced software?

Absolutely. Even small contractors gain accuracy, save time, and improve client communication using modern estimation tools.

How much contingency should I include?

Typically, 5-10%, depending on project complexity and risk level.

What are the most common causes of inaccurate estimates?

Incomplete scope, ignored soft costs, lack of current pricing data, and insufficient contingency buffers.