Introduction

Managing costs in commercial projects is critical to ensuring profitability and success. With numerous variables and potential pitfalls, a well-thought-out strategy is essential. This comprehensive guide will explore the top strategies for managing costs in commercial projects, providing actionable insights and real-world examples to help you navigate this complex landscape.

The Importance of Cost Management in Commercial Projects

Cost management is not just about cutting corners; it’s about optimizing resources to achieve the best possible outcomes. Effective cost management ensures that projects stay within budget, meet deadlines, and deliver high-quality results. By implementing robust cost management strategies, you can mitigate risks, enhance stakeholder satisfaction, and drive business growth.

Key Strategies for Managing Costs in Commercial Projects

Managing costs in commercial construction requires a holistic approach beyond budgeting alone. It involves continuous planning, leveraging innovative techniques, and maintaining strong partnerships. Below are the top strategies that form the backbone of effective cost management in commercial projects.

1. Budget Planning and Forecasting

Accurate Budgeting

Creating a precise and comprehensive budget is the cornerstone of cost control in any construction project. This begins with a thorough estimation of all expenses, including:

- Labor costs (salaries, benefits, subcontractors)

- Material costs (raw materials, prefabricated elements)

- Equipment and machinery

- Permits, inspections, and compliance costs

- Site preparation and utilities

- Administrative and overhead expenses

Best Practices:

- Use historical data from past projects to benchmark expenses.

- Consult with subject matter experts to validate assumptions and cost estimates.

- Factor in market trends such as material price fluctuations or labor shortages.

Regular Forecasting

A static budget becomes outdated quickly in dynamic project environments. Continuous forecasting allows you to adjust financial expectations in response to evolving project variables.

Key Actions:

- Monitor actual vs. projected costs weekly or bi-weekly.

- Update your budget when there are changes in scope, resource availability, or market prices.

- Use forecasting software to create financial models that simulate different scenarios and outcomes.

2. Value Engineering

Identifying Cost-Saving Opportunities

Value engineering is not about cutting corners but maintaining quality while finding cost-effective solutions. This process evaluates each project element to uncover areas where savings can be realized without compromising functionality or aesthetics.

Benefits of Value Engineering:

- Improves cost efficiency

- Encourages innovation and flexibility

- Increases project value and stakeholder satisfaction

Implementation Steps

- Conduct a Thorough Analysis: Break down the entire project into its individual systems (e.g., HVAC, electrical, structural). Review the cost and purpose of each.

- Collaborate with Stakeholders: Involve architects, engineers, contractors, and even vendors. Each party brings unique perspectives that can uncover creative solutions.

- Evaluate Alternatives: Explore multiple materials, construction methods, and layouts options. Compare the life-cycle costs, not just upfront expenses.

Example: Replacing steel beams with engineered timber may reduce costs and offer sustainable benefits without sacrificing structural integrity.

3. Efficient Project Management

Lean Construction Techniques

Lean construction is a project management philosophy that aims to maximise value while minimizing waste. It emphasizes continuous improvement, efficient workflows, and respect for the workforce.

Lean Techniques Include:

- Just-in-time material delivery to avoid storage costs and damage

- Standardizing workflows to reduce delays and confusion

- Prefabrication to reduce labor time on-site

Project Management Software

Project management tools are essential for organizing complex workflows and keeping the project on schedule and within budget.

Recommended Software:

- Asana & Trello: Great for task management and team communication.

- Microsoft Project: Ideal for scheduling and resource allocation.

- Procore or Buildertrend: Industry-specific tools for construction project tracking and financial control.

Implementation Steps

- Adopt Lean Principles: Train your team in lean methodologies like Six Sigma or Last Planner System to ensure a culture of efficiency.

- Use Technology: Utilize software dashboards to visualize project progress, financial health, and resource utilization.

- Regular Reviews: Hold weekly reviews to assess KPIs and take corrective action early.

4. Supplier and Vendor Management

Building Strong Relationships

Vendors and suppliers play a critical role in managing material and equipment costs. Fostering long-term relationships can result in better pricing, priority service, and collaborative problem-solving.

Strategies to Strengthen Supplier Ties:

- Maintain open communication about project timelines and expectations.

- Provide timely payments to foster goodwill.

- Involve suppliers in planning stages for more accurate lead times and cost forecasting.

Implementation Steps

- Negotiate Terms: Focus on price, lead times, payment flexibility, and penalties for delays.

- Bulk Purchasing: Consolidate orders across projects to qualify for volume discounts.

- Long-Term Partnerships: Establish framework agreements with dependable vendors to ensure consistency in price stability and supply chain.

5. Risk Management

Identifying Potential Risks

Early risk identification prevents future budget overruns and project delays. Risks may include labor shortages, equipment failure, weather disruptions, or unexpected site conditions.

Risk Categories:

- Financial: Cash flow, inflation, interest rates

- Operational: Equipment breakdown, supply chain delays

- Legal: Permits, contract disputes, compliance issues

Mitigation Strategies

Proper risk mitigation minimizes the likelihood and impact of negative events.

Examples of Risk Mitigation:

- Purchasing builder’s insurance and liability coverage

- Creating backup vendor lists for critical supplies

- Establishing dispute resolution protocols in contracts

Implementation Steps

- Conduct Risk Assessments: Use tools like SWOT analysis or Monte Carlo simulations to assess probability and impact.

- Develop Contingency Plans: Allocate a percentage of the budget as a contingency fund for high-risk items.

- Implement Quality Control: Set up robust inspection processes to reduce rework and maintain construction standards.

6. Technology and Innovation

Leveraging Technology

Technology is revolutionizing how commercial construction projects are executed. From 3D modeling to drone surveys, these tools enable faster, more accurate decision-making and cost savings.

Key Technologies:

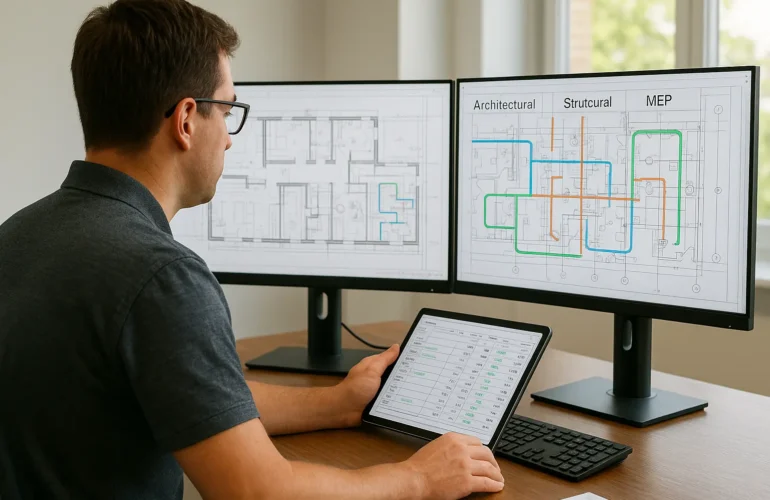

- Building Information Modeling (BIM): Detects design conflicts before construction begins.

- Drones: Provide real-time aerial views for site inspections and progress tracking.

- Virtual Reality (VR): Allows stakeholders to visualize spaces and identify design flaws early.

Implementation Steps

- Adopt BIM: Incorporate BIM to centralize project data and improve coordination between architects, engineers, and contractors.

- Use Drones for Surveys: Save time and labor costs by conducting faster, more accurate site assessments.

- Virtual Reality Design Reviews: Host immersive design sessions with clients and teams to streamline approvals and avoid late-stage changes.

By executing these expanded and actionable strategies, construction professionals can manage costs effectively and deliver higher-quality results that drive long-term project success. Let me know if you’d like these formatted for SEO or turned into downloadable content.

Real-World Examples and Case Studies

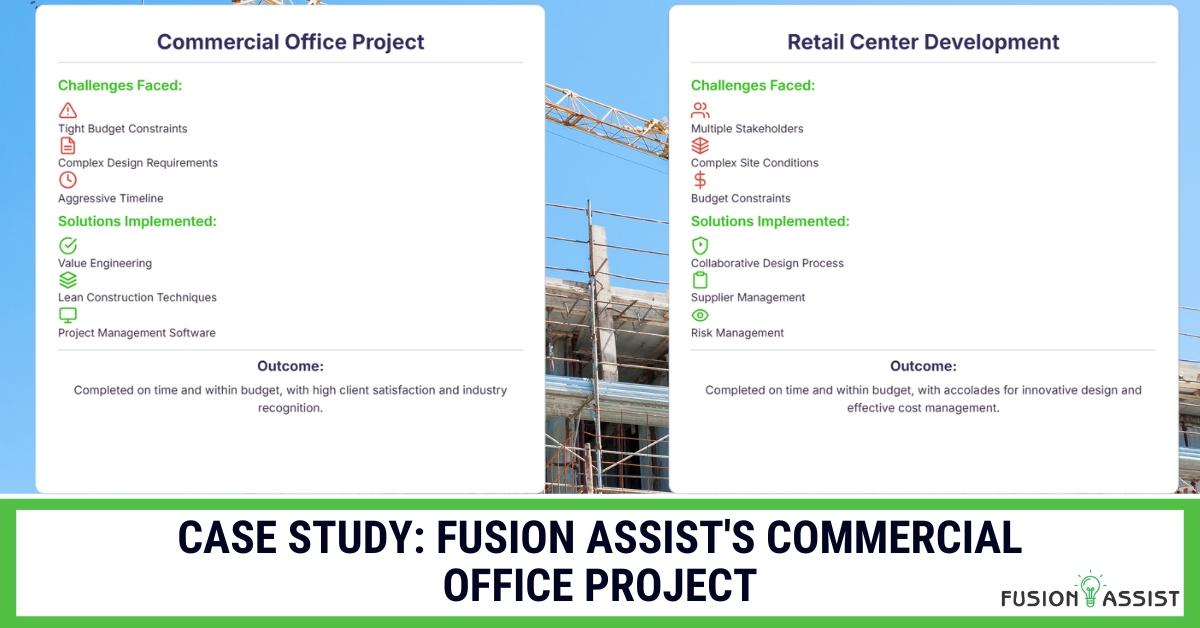

Case Study: Fusion Assist’s Commercial Office Project

Project Overview

Fusion Assist was contracted to build a new commercial office building for a tech company. The project involved a complex design with high-end finishes and advanced technological infrastructure.

Challenges Faced

- Tight Budget Constraints: The client had a strict budget, making cost management critical.

- Complex Design Requirements: The project required specialized materials and advanced construction techniques.

- Aggressive Timeline: The project had to be completed within 12 months to meet the client’s occupancy schedule.

Solutions Implemented

- Value Engineering: Fusion Assist conducted a value engineering exercise to identify cost-saving opportunities. They proposed alternative materials and design modifications that reduced costs without compromising quality.

- Lean Construction Techniques: They implemented lean construction techniques to optimize resource allocation and reduce waste. This included just-in-time material delivery and efficient workflow management.

- Project Management Software: Utilizing project management software, they tracked progress in real-time, identified potential delays, and took corrective action promptly.

Outcome

The project was completed on time and within budget. The client was highly satisfied with the results, and the project received industry recognition for its innovative approach and cost management strategies.

Case Study: Fusion Assist’s Retail Center Development

Project Overview

Fusion Assist was tasked with developing a new retail centre. The project involved multiple stakeholders, complex site conditions, and a tight budget.

Challenges Faced

- Multiple Stakeholders: Coordinating with multiple stakeholders, including retailers, suppliers, and local authorities, was a significant challenge.

- Complex Site Conditions: The site had challenging terrain and required extensive grading and stabilization.

- Budget Constraints: The project had a strict budget, making cost management essential.

Solutions Implemented

- Collaborative Design Process: Fusion Assist fostered a collaborative environment between architects, engineers, and stakeholders. Regular meetings and open communication channels helped align all parties and identify potential issues early.

- Supplier Management: They developed strong relationships with suppliers, negotiating favorable terms and securing bulk purchase discounts.

- Risk Management: A thorough risk assessment identified potential risks, and mitigation strategies were developed to address them. This included purchasing insurance and implementing quality control measures.

Outcome

The retail center was completed on time and within budget. The project received accolades for its innovative design and effective cost management strategies.

FAQs

How can I reduce costs without compromising quality?

Value Engineering and Lean Construction Techniques

Implement value engineering to identify cost-saving opportunities without compromising quality. Utilize lean construction techniques to optimize resource allocation and reduce waste.

What role does project management software play in cost management?

Tracking Progress and Identifying Delays

Project management software helps track progress in real-time, manage resources efficiently, and identify potential delays. This proactive approach allows you to take corrective action promptly and avoid cost overruns.

How can I negotiate better terms with suppliers?

Develop Strong Relationships and Explore Bulk Purchasing

Develop strong relationships with suppliers and explore bulk purchasing options to secure better pricing and service. Long-term partnerships can also lead to additional benefits such as timely deliveries and priority support.

What are the benefits of using Building Information Modeling (BIM)?

Enhanced Efficiency and Decision-Making

BIM enhances efficiency by identifying design conflicts early, optimizing construction sequences, and improving decision-making. This results in reduced rework and cost savings.

How can I manage risks effectively in a commercial project?

Conduct Thorough Risk Assessments and Develop Mitigation Strategies

Conduct a thorough risk assessment to identify potential risks and develop mitigation strategies. Allocate contingency funds where necessary and implement quality control measures to prevent defects and rework.

Conclusion

Managing costs in commercial projects is a multifaceted challenge that requires a strategic and proactive approach. By implementing robust cost management strategies, leveraging technology, and fostering collaboration, you can optimize resources, mitigate risks, and deliver high-quality results. Whether you are a project manager, contractor, or stakeholder, understanding and applying these strategies is essential for achieving project success.

Contact Fusion Assist to streamline your commercial project costs through expert planning, innovation, and proven results