Introduction

The Dallas-Fort Worth construction business is a competitive one, and every contractor requires an advantage. It does not matter whether you are constructing skyscrapers in town or designing new suburbs, you cannot be the lowest bidder in order to win a project. This is even more complicated in public works, where a tangled network of so-called prevailing wage laws determines what you have to pay your workers. These regulations are a financial landmine and paperwork nightmare to many Dallas contractors. A minor error in a wage determination may cost large fines, stressful audits and even the next government work.

But what would happen if you could convert this challenge to a competitive advantage? Consider charting the course of prevailing wage estimates without a hint of apprehension, being compliant with the laws of the land and being the first stop to the money-making public projects. It is not only about staying out of punishment, but learning a system that can trick your rivals. A good, professional prepared prevailing wage estimate will safeguard your profits, gain the confidence of the agencies and win you more profitable work.

This is a guide to general contractors and subcontractors in Dallas. We will deconstruct prevailing wage laws, address the most common difficulties, and provide a clear way of ensuring you never get your estimates wrong. And we are going to demonstrate how working with a specialized service such as Fusion Assist can make the guesswork out of estimation, and you can go back to what you do best: building Dallas.

What Exactly Are Prevailing Wages in Dallas?

It is important to understand the concept well before we discuss strategy. Minimum wage is not prevailing wages. They consist of a certain rate of pay inclusive of fringe benefits that is determined by the government on workers in publicly funded construction projects. The aim is to ensure that the government contracts do not undermine the local labor standards. This makes a huge difference in a busy market such as Dallas.

Defining the Terms: Wages, Fringe Benefits, and Total Compensation

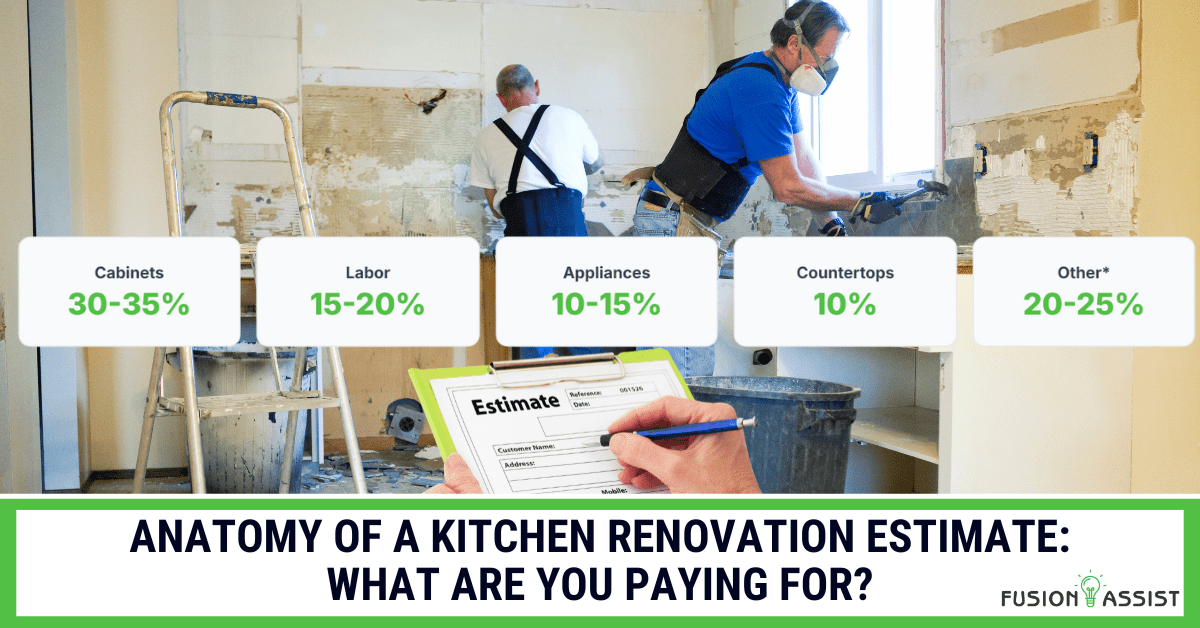

The current wage consists of two important components:

- The Basic Hourly Rate: This is the minimum hourly pay for a worker in a specific trade (like an electrician or carpenter) on a covered project.

- Fringe Benefits: This is an extra, employer-paid amount per hour that covers things like health insurance, retirement plans, vacation pay, and apprenticeship training.

As a contractor, you have to pay a total compensation package that is equal to or higher than the sum of these two figures. It is possible to pay all as straight wage or to mix a lower hourly pay with good benefits package. One of the most difficult aspects of prevailing wage estimation in Dallas is how to compute and apportion these fringe benefits.

The Legal Backbone: The Davis-Bacon Act and Texas State Laws

The source of these rules to Dallas contractors is normally two-fold:

- The Federal Davis-Bacon and Related Acts (DBRA): This is a federal legislation that covers construction contracts with the U.S government worth more than 2000. This act applies to you in case you are bidding on a federal project in Dallas such as work on a military base or VA hospital.

- Texas Government Code Chapter 2258: While Texas doesn’t have a statewide “Little Davis-Bacon Act,” this law requires that workers on state or local public projects (like for the City of Dallas) are paid the “general prevailing rate of per diem wages” for similar work in the area.

The first big challenge in the bidding process is to know what law to apply and determine the proper wage rates.

The High Stakes of Inaccuracy: Major Challenges for Dallas Contractors

The concept of prevailing wages is quite straightforward, but its implementation is not. To an active contractor, administrative work can be too much. These are the greatest pitfalls that cause costly errors.

The concept of prevailing wages is quite straightforward, but its implementation is not. To an active contractor, administrative work can be too much. These are the greatest pitfalls that cause costly errors.

Challenge 1: Deciphering Complex Wage Determinations

A wage determination document contains the formal pay rates within a county in every job classification. Such documents may be lengthy and incomprehensible. One of the most frequent is the misclassification of a worker-paying a person the laborer rate when his or her responsibilities should be assessed as those of a carpenter. This one error compounded throughout an entire project can cost you thousands in back wages and penalties.

Challenge 2: The Nightmare of Certified Payroll Reporting

The prevailing wage jobs require impeccable record-keeping. The largest one is the filing of weekly certified payroll reports. These reports necessitate an explicit analysis of every employee in terms of their hours, job category, salaries and perks. A single error or a late filing may initiate an audit and stop your project payments.

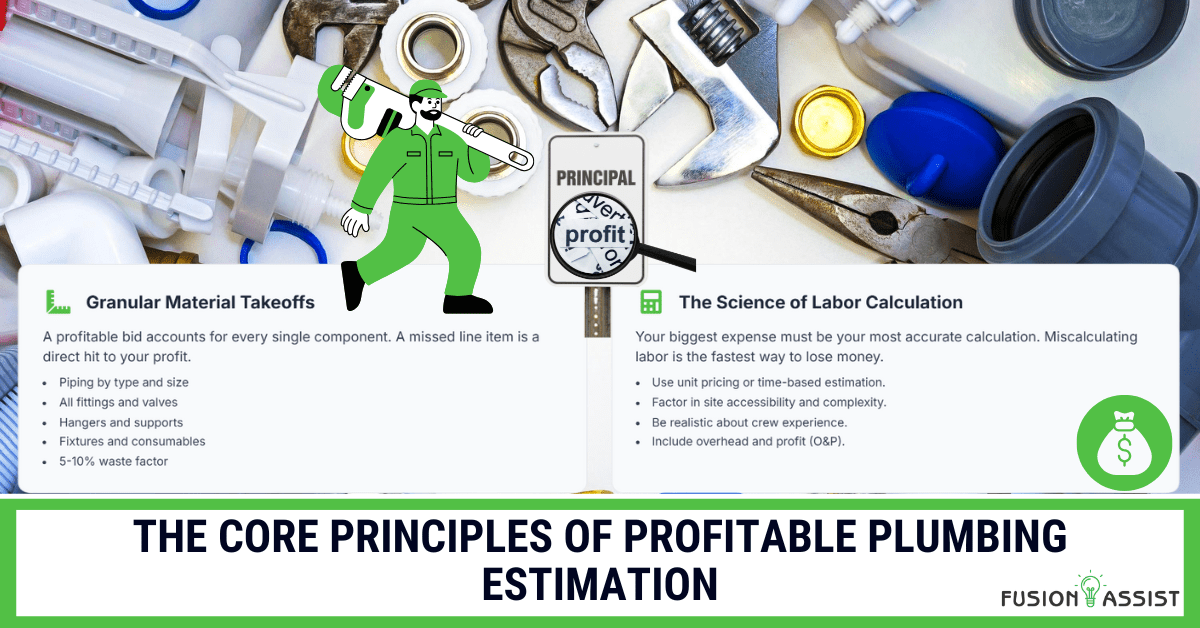

Challenge 3: Calculating and Allocating Fringe Benefits

This is what most contractors fall short of. The credit on fringe benefits cannot be computed by dividing the amount you paid monthly on insurance by the number of hours you worked. It has certain rules and in case you do not get them right, an auditor can disallow your credit, and you will be forced to pay the entire fringe amount in cash.

Challenge 4: The Constant Threat of Audits and Penalties

Government agencies take wage compliance seriously. A worker complaint or a random check will initiate an audit. The consequences are severe:

- Payment of back wages to all underpaid workers.

- Significant financial penalties and fines.

- Withholding of contract payments until the issue is resolved.

- The debarment which removes you, up to three years, as a government contractor.

Your Solution Partner: Leveraging Fusion Assist for Flawless Estimation

It is obvious, with such risks, guesswork is not an option. The complexity of the details to be provided demands a professional treatment. Hiring a professional estimation service provider such as Fusion Assist can transform the situation, and the risk of the government contract bidding in Dallas will become a thing of the past.

It is obvious, with such risks, guesswork is not an option. The complexity of the details to be provided demands a professional treatment. Hiring a professional estimation service provider such as Fusion Assist can transform the situation, and the risk of the government contract bidding in Dallas will become a thing of the past.

How Fusion Assist Transforms Your Bidding Process

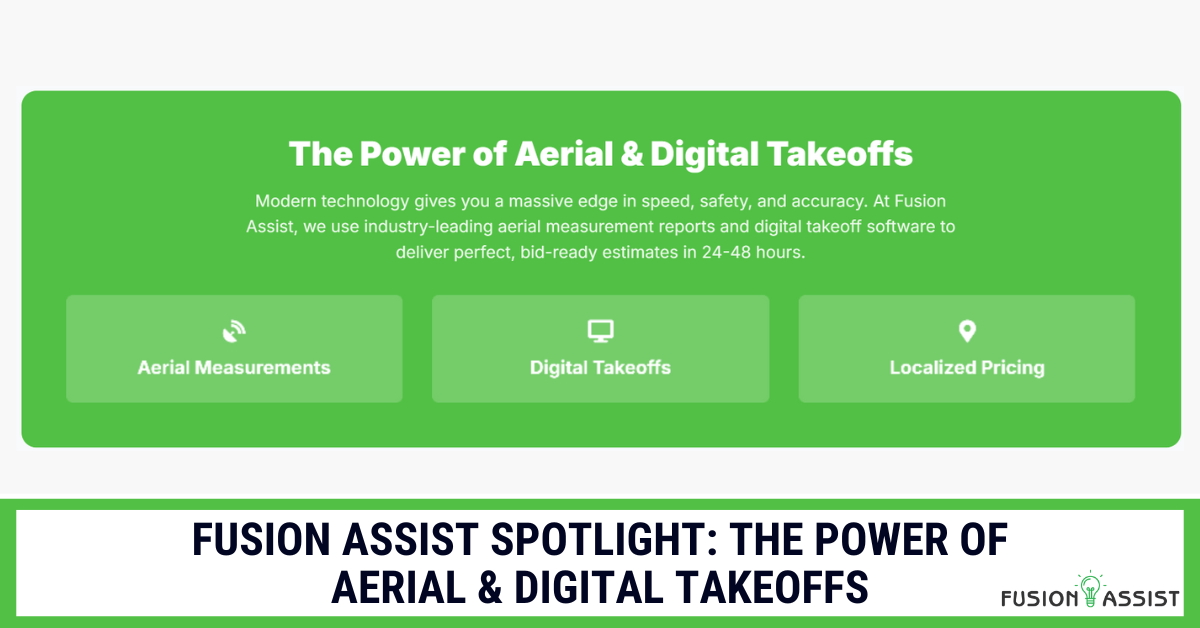

You can leave the entire process to a group of specialists and devote your time to other issues instead of trying to understand wage determinations over several hours. We are a speed and accuracy driven process.

Step 1: Submitting Your Dallas Project Plans

The whole process begins as you submit your project plans to us. Our team promptly conducts the scope of work and the peculiarities of the Dallas area needs.

Step 2: Accessing Localized, Up-to-Date Wage Data

We employ an all-inclusive database of material and labor costs, the most up-to-date federal and Texas wage determinations in Dallas County. We align each work to the appropriate worker category and this is done with 100 percent accuracy.

Step 3: Receiving a Detailed, Bid-Ready Estimate

In 24-48 hours, you obtain the professional bid package. It is not a mere number, but rather an elaborate analysis of all the labor costs, in a format where your company logo appears and the report is ready to be submitted. This relieves you to work on client relations and project strategy.

Case Study: A Dallas Contractor’s Success on a City Park Project

Client

A mid-sized general contractor in Dallas.

Challenge

Fusion Assist Solution

The contractor forwarded the bid documents to Fusion Assist. We did a thorough take off and we cross referenced each activity with the right wage rate in Dallas County. It took the contractor two days to have a full, precise, and professionally branded bid.

Result

The contractor had a solid estimate and they placed their bid with confidence. They were awarded the contract, which they attributed to the fast and professional nature of Fusion Assist estimate that enabled them to stand out. They completed the project on a profit basis and without any compliance.

Key Considerations for Your Next Prevailing Wage Bid

The most effective option is to join forces with a specialist, yet it is beneficial that your team learns several important concepts:

- Worker Classification is Crucial: Never classify a worker on the basis of his or her job title..

- Don’t Forget Overtime Rules: Both federal and Texas laws require overtime pay (1.5x the base rate) for all hours worked over 40 in a week on a covered project.

- Document Everything: Meticulous records are your best defense in an audit. Keep detailed logs of hours, tasks, and benefits for every worker.

Conclusion: From Compliance Burden to Competitive Edge

A prevailing wage project is an enormous opportunity in the Dallas construction scene. Nonetheless, they require accuracy that can be overwhelming even to the most experienced contractors. Through a strategic approach, which consists of learning the rules, knowing the challenges and collaborating with expert partners, you can turn this complicated requirement into a strong competitive advantage.

Quit struggling with messy wage tables and paperwork. A proper professional estimate will create trust, safeguard your bottom line and distinguish you. Whether you need a bid-ready prevailing wage estimate to win one of the high-paying public works projects that define the future of Dallas or want to gain access to all the prevailing wage estimates needed to win the most bids, you can count on Fusion Assist to provide the bid-ready prevailing wage estimate that gives you the power to win more of the high-paying public works projects that define the future of Dallas.

Stop wrestling with complex wage determinations and start winning more profitable bids. Contact Fusion Assist to get your fast, compliant, and bid-ready estimate.

Frequently Asked Questions (FAQs)

What is the greatest error contractors have on prevailing wage jobs?

Misclassification of workers is the most prevalent and the most expensive error. The non-intentional but still direct violation is to pay a skilled craftsman at the rate of a general laborer, which will be detected during an audit and cause huge fines. It is of paramount importance that daily activities are aligned to the formal job categories.

Is it possible to pay my workers at the standard rate and cover the rest in cash?

No. Any form of payment should be recorded by official payroll. The use of side cash payments is unlawful, against the taxation regulations, and will lead to dire repercussions in the event that it is found out.

Is my subcontractors covered under prevailing wage laws?

Yes, absolutely. Being the prime contractor, it is your obligation to make sure that all the subcontractors within the job site are compliant. Failure to do so will turn out to be your liability.

What is the frequency of change of the prevailing wage rates of Dallas?

Wages are also revised on a regular basis in order to capture the local economy. The correct wage determination must be used based on the one you have in your particular contract and not an old one in a previous job.

How will an estimation service assist me with an audit?

A professional service such as Fusion Assist offers a straight forward, line by line breakdown of your work expenses. This third-party documentation by a professional, in an audit, proves your bid and payroll, and demonstrates that you have done your due diligence, and makes the process so much easier.