Introduction

The decision to hire unionized labor for construction projects is a pivotal one for contractors and project owners. This choice significantly impacts budgets, timelines, quality, safety, and operational flexibility.

Understanding the unique characteristics of both union and non-union workforces is crucial for any firm navigating today’s competitive landscape. This guide will explore the pros and cons of hiring union labor for construction projects, offering a balanced perspective to inform your strategic decisions.

Understanding Union Labor in Construction

A construction union is a collective organization of workers, typically within specific trades, that bargains collectively with employers over wages, benefits, and working conditions. When a company hires union labor, it usually enters into a collective bargaining agreement (CBA). This agreement sets forth detailed terms of employment, encompassing wages, benefits, work rules, and hiring practices, offering a structured approach to labor relations.

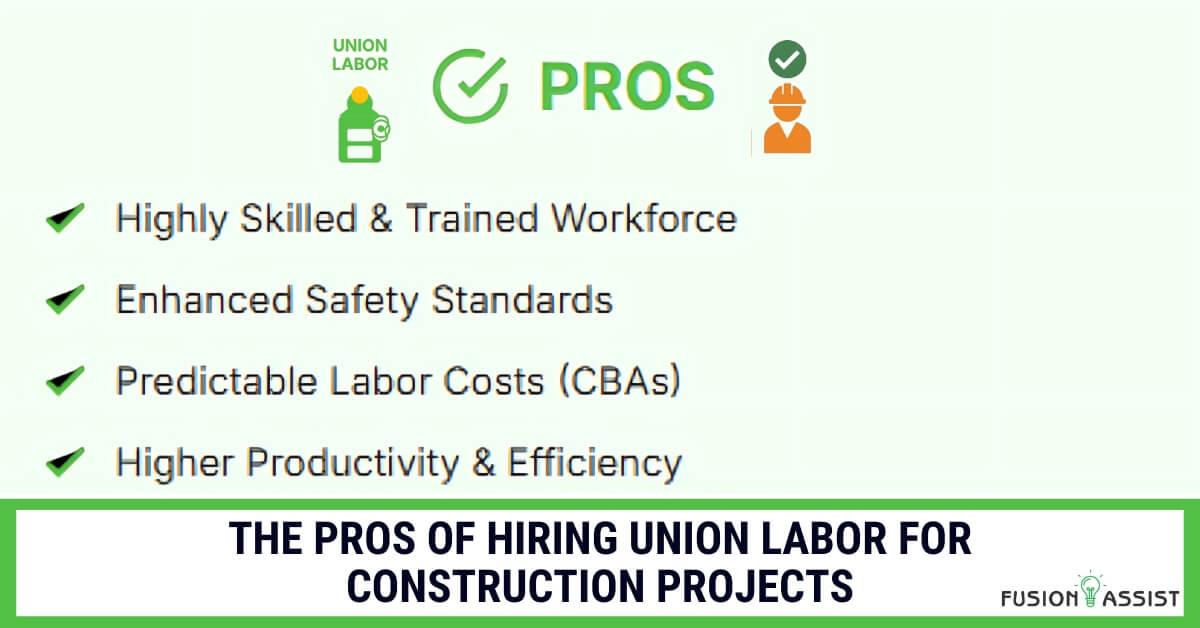

The Pros of Hiring Union Labor for Construction Projects

Engaging a union workforce can bring several compelling benefits to construction projects, particularly on large or complex endeavours.

Access to a Highly Skilled and Trained Workforce

One of the most significant advantages of hiring union labor is the access to a consistently skilled workforce. Unions heavily invest in rigorous apprenticeship programs and ongoing training for their members.

Rigorous Apprenticeship Programs

Union apprenticeships are typically multi-year programs that combine extensive on-the-job training with comprehensive classroom instruction. This approach consistently produces highly competent and certified journeymen across various trades, ensuring a strong foundation of expertise.

Continuous Professional Development

Unions often provide ongoing education to keep their members updated on the latest techniques, technologies, and safety protocols. This commitment to continuous learning ensures a high level of craftsmanship and efficiency on the job site.

Ready Pool of Specialized Expertise

For complex construction projects requiring specialized skills (e.g., structural steelwork, intricate electrical systems), union halls can often quickly provide certified and experienced craftspeople. This ready access to a pool of proficient workers can significantly contribute to higher quality work and reduced rework, ultimately positively impacting project timelines and budgets.

Enhanced Safety Standards and Performance

Safety is paramount in construction, and union labor is often strongly committed to high safety standards.

Comprehensive Safety Training

Union training programs emphasize extensive safety education, often exceeding minimum regulatory requirements. This includes specific training for hazardous materials, equipment operation, and emergency procedures.

Strong Safety Culture

Unions typically foster a robust safety culture among their members, who are often empowered to identify and report unsafe conditions without fear of reprisal. This proactive approach can lead to fewer project delays, reduced workers’ compensation claims, and a healthier workforce.

Potentially Reduced Accident Rates

Studies, such as those conducted by the Construction Industry Institute, have indicated that union sites may have lower accident rates due to better training and adherence to safety protocols. A safer site leads to greater project efficiency and a more productive environment, critical factors in the successful planning of large-scale construction projects.

Higher Productivity and Efficiency

While often associated with higher wages, union labor can also lead to increased productivity and efficiency on construction projects.

Experienced and Stable Workforce

The extensive training and experience of union workers, combined with lower employee turnover due to better benefits and working conditions, lead to a more stable workforce. This stability means less time spent on recruitment and training new hires, and more institutional knowledge retained on site, contributing to faster and more accurate task completion.

Standardized Work Practices

Unions often promote standardized work practices across their members, which can lead to greater predictability and consistency in project execution. For projects with tight schedules, a highly competent and stable workforce can be invaluable. This can also tie into compliance, as consistent work practices can help avoid issues related to prevailing wage compliance, which is vital on public works.

Predictable Labor Costs and Negotiations

Operating under a collective bargaining agreement (CBA) brings a degree of predictability to labor costs.

Standardized Wage Scales

Wages and benefits are predetermined for the duration of the CBA, allowing for more accurate bidding and budgeting. This eliminates the volatility associated with fluctuating market rates for individual non-union hires.

Streamlined Negotiations

Contractors do not need to negotiate wages and benefits with individual employees, streamlining the administrative burden. CBAs typically include clear grievance procedures, which can help resolve workplace disputes efficiently, preventing minor issues from escalating into major disruptions. This predictability is a significant advantage when planning for large-scale construction projects where financial forecasting is paramount.

Stronger Labor Relations and Advocacy

Unions serve as a formal communication channel between labor and management.

Organized Worker Representation

Unions provide a structured way for workers to voice concerns, improving morale and reducing individual grievances, fostering a more positive and fair working environment.

Political and Industry Influence

Unions often have significant political and industry influence, which can sometimes benefit union contractors in securing public works contracts or navigating regulatory landscapes.

The Cons of Hiring Union Labor for Construction Projects

Despite the benefits, hiring union labor also presents potential drawbacks that must be carefully evaluated.

Higher Overall Labor Costs

Higher Overall Labor Costs is often the most cited disadvantage of hiring union labor.

Higher Base Wage Rates

Union workers typically command higher hourly wage rates than their non-union counterparts, as dictated by collective bargaining agreements.

Extensive Fringe Benefit Contributions

The comprehensive benefits packages (health insurance, retirement plans, training funds) add significantly to the overall labor costs beyond just wages. These are mandatory contributions that can surpass those offered by non-union firms.

Strict Overtime and Work Rule Restrictions

CBAs often contain strict rules regarding overtime pay (e.g., double time for weekends or holidays), shift differentials, and minimum call-out pay, which can significantly increase project costs if not meticulously managed. For projects with very tight budgets or highly competitive bidding environments, these higher costs can be a significant hurdle.

Reduced Flexibility and Control

The structured nature of collective bargaining agreements can sometimes limit a contractor’s operational flexibility.

Restrictive Work Rules and Jurisdictional Lines

CBAs can dictate specific tasks for each trade, potentially leading to inefficiencies if workers from one trade are prohibited from performing tasks that technically fall under another union’s jurisdiction, even if they are capable. Disputes over the division of work between different trades (demarcation disputes) can lead to slowdowns or work stoppages.

Limitations on Hiring Practices

Contractors may have less control over who they hire, as they might be required to source labor primarily through union halls, potentially limiting their ability to select specific individuals based on personal relationships or past performance outside the union system. This lack of flexibility can be a challenge on dynamic construction projects where quick adaptation is necessary.

Potential for Strikes and Work Stoppages

While unions aim to provide stability, the collective bargaining process inherently carries the risk of strikes or lockouts.

Disruptions from Contract Negotiations

If negotiations for a new CBA break down, unions may call for a strike, leading to complete work stoppages that can severely derail project schedules and incur significant financial penalties.

Sympathy Strikes and Picketing

In some cases, unions may engage in sympathy strikes to support other striking unions, even if the primary employer’s contract is not in dispute. Union picketing can also deter non-union workers, suppliers, and deliveries, causing further disruptions. The threat or reality of a strike represents a major project risk that needs to be factored into planning.

Increased Administrative Burden and Compliance

Managing a union workforce involves specific administrative requirements.

Strict Adherence to CBAs

Strict adherence to all terms of the collective bargaining agreement is mandatory, requiring detailed record-keeping and payroll management to ensure compliance with complex wage and benefit structures.

Extensive Reporting Requirements

Unions often have extensive reporting requirements related to hours worked, contributions to benefit funds, and apprentice utilization. Managing these processes can be time-consuming and require dedicated resources. Failure to comply with CBA terms can lead to grievances, fines, or even legal action, adding another layer of complexity to construction projects.

Perceived Loss of Project Autonomy

For contractors accustomed to a non-union model, integrating union labor can feel like a loss of autonomy.

Union Oversight on Site

Unions may have stewards on site who monitor compliance with the CBA and advocate for union members’ interests, which can sometimes be perceived as interference by management. Decision-making regarding certain aspects of labor management (e.g., promotions, layoffs, disciplinary actions) may be subject to union rules and grievance procedures rather than solely management discretion.

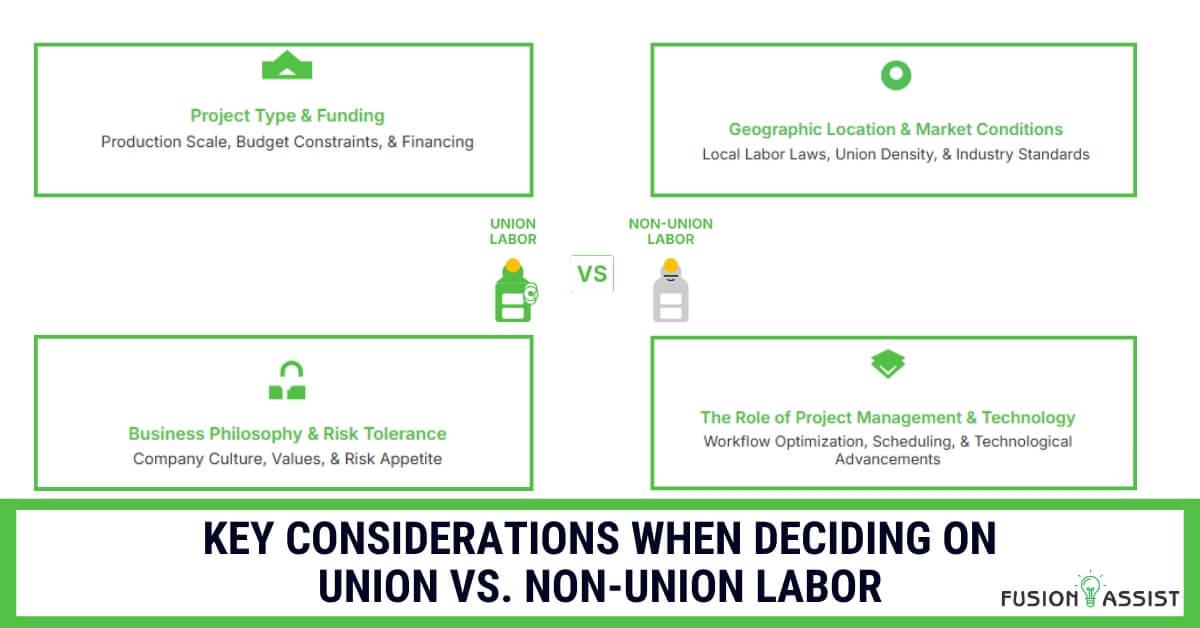

Key Considerations When Deciding on Union vs. Non-Union Labor

The decision to hire union labor is rarely black and white. Several factors should influence your approach to construction projects.

Project Type and Funding

Many government-funded construction projects (federal, state, and local) are subject to prevailing wage laws. While these laws apply to all workers, union contractors are often well-versed in compliance, and union wages frequently meet or exceed prevailing wage requirements. This can make hiring union a simpler path to compliance. For large, complex projects requiring a vast, skilled workforce, unions can be an effective pipeline for talent. In the private sector, the choice is usually more flexible, driven by market conditions and cost competitiveness.

Geographic Location and Market Conditions

Labor market dynamics vary significantly by region. Some areas have a strong union presence and robust union halls, making union labor readily available and potentially more efficient to mobilize. In other regions, non-union labor may dominate, offering greater availability and competitive rates.

Business Philosophy and Risk Tolerance

Consider your company’s long-term vision and existing relationships. Do you prefer a highly structured labor environment with standardized wages and benefits, or do you prioritize maximum flexibility? Evaluate your tolerance for potential risks such as strikes and higher fixed labor costs versus the benefits of a trained, stable, and safety-conscious workforce. Effective risk management planning is crucial regardless of your labor choice.

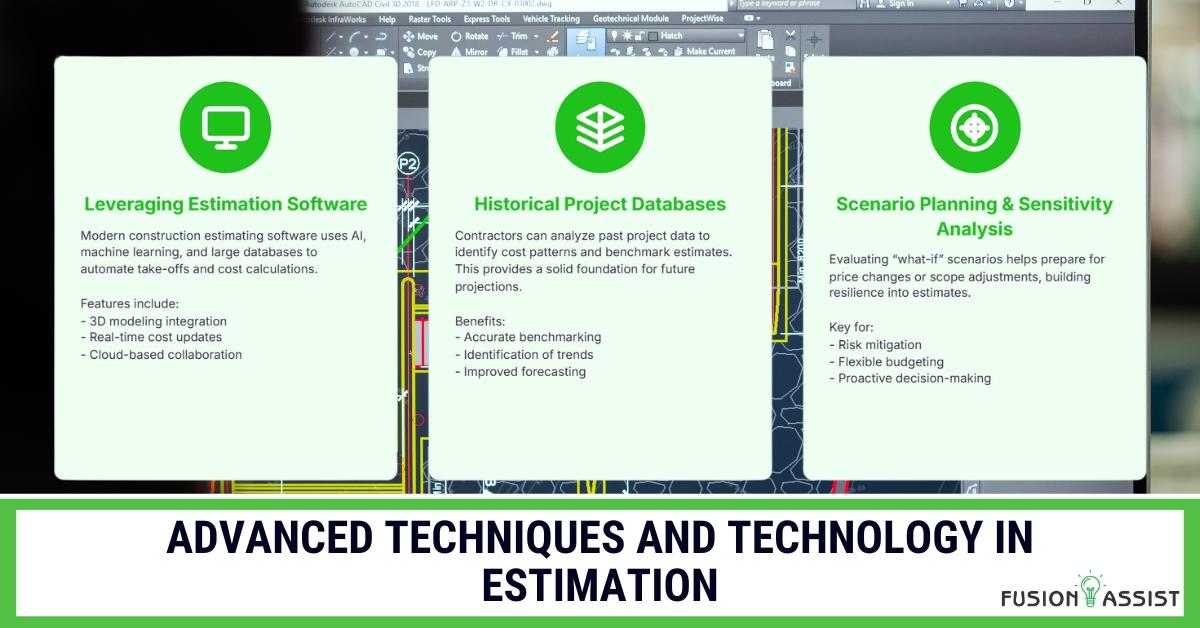

The Role of Project Management and Technology

Regardless of whether you choose union or non-union labor, robust project management and the strategic use of technology are paramount. Tools like Building Information Modeling (BIM) can help optimize resource allocation and improve collaboration, regardless of labor structure.

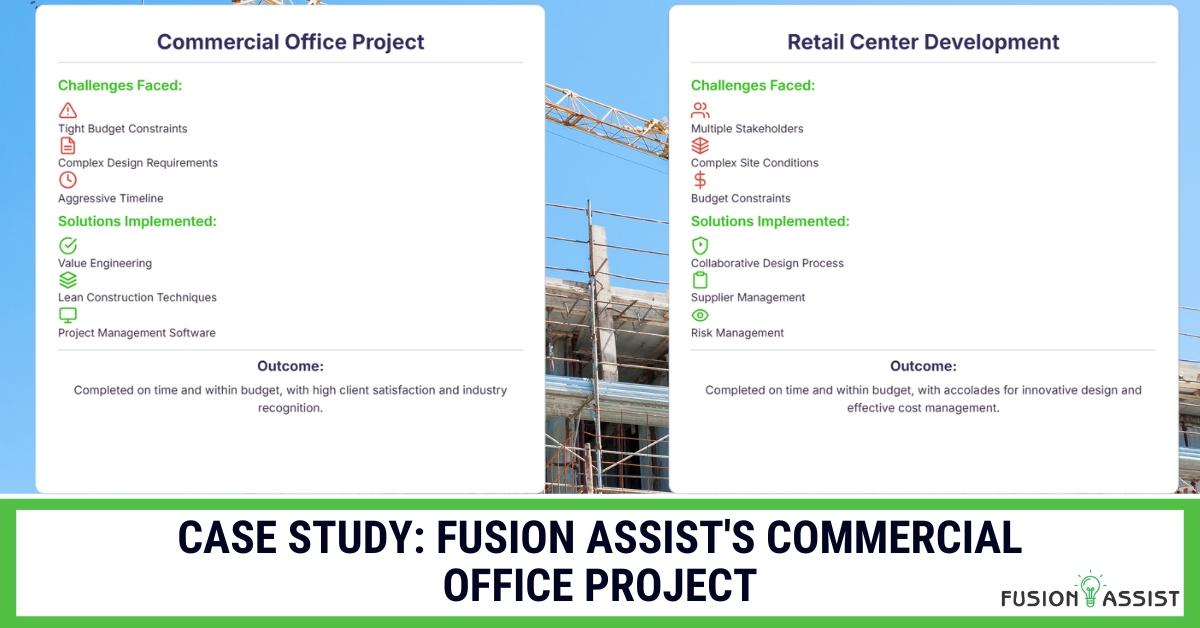

Real-World Application: Navigating Labor Decisions with Fusion Assist

The complexities of labour decisions in construction are not merely theoretical; they have tangible impacts on project delivery. This is where strategic partners and advanced solutions become invaluable.

For example, consider a large public works infrastructure project. The project is federally funded, making prevailing wage compliance a critical factor. The general contractor, accustomed to non-union work, faces a dilemma: stick with their established non-union workforce and rigorously manage prevailing wage adherence, or consider hiring union labour, which often simplifies this compliance.

Fusion Assist’s expertise can be instrumental in such a scenario:

Pre-Bid Cost Analysis

Fusion Assist could provide a detailed comparative analysis of labour costs for both union and non-union scenarios, factoring in not just wages but also benefits, training costs, and potential productivity differentials. Their software might simulate project costs under different labor models, giving the contractor a clear financial picture before bidding.

Resource Mobilization & Scheduling

If the contractor chooses to work with a union, Fusion Assist’s project management platform can integrate directly with union hall dispatch systems (where applicable), streamlining the process of sourcing the required skilled workforce. Their tools can optimize detailed schedules, factoring in union work rules and ensuring efficient deployment of specific trades, minimizing potential delays.

Compliance Monitoring

For either union or non-union projects under prevailing wage requirements, Fusion Assist’s compliance features can help automate tracking of worker classifications, hours, and pay rates against stipulated determinations, significantly reducing the administrative burden and mitigating the risk of penalties.

Risk Mitigation Strategies

Fusion Assist’s risk management modules can help identify, analyze, and plan responses for labour-related risks. This includes modelling the potential impact of labour disputes or jurisdictional issues, allowing the contractor to build contingency plans into their overall project planning.

By leveraging Fusion Assist’s comprehensive project management solutions, contractors can move beyond guesswork. They can make data-driven decisions about their labor strategy, whether it’s embracing a full union workforce, maintaining a non-union structure, or managing a mixed approach, ensuring higher efficiency and successful project outcomes.

Conclusion

The decision to hire union labor for construction projects is a complex strategic choice with significant implications. Both union and non-union models offer distinct advantages and disadvantages that must be weighed against your project’s unique demands, your company’s operational philosophy, and the prevailing market conditions.

Ultimately, successful construction projects are built on meticulous planning, efficient execution, and effective management of all resources, especially labor. By thoroughly understanding the pros and cons of hiring union labor and by leveraging expert guidance and advanced project management tools, you can make a strategic choice that lays the foundation for a successful, high-quality, and profitable build.

Make smart labor choices. Connect with Fusion Assist today!

Frequently Asked Questions (FAQs)

Q1: Do union workers always cost more than non-union workers?

A: Generally, yes, union workers typically have higher hourly wage rates and more comprehensive fringe benefits (health, pension, training funds) due to collective bargaining agreements. This usually results in a higher overall labor cost per hour. However, it’s important to consider potential offsets like higher productivity, lower turnover, and reduced rework, which can sometimes lead to comparable or even lower overall project costs.

Q2: Are union construction sites safer than non-union sites?

A: While safety depends on the individual contractor’s commitment, studies and industry observations often suggest that union construction projects may have lower accident rates. This is attributed to the extensive, formalized safety training programs unions provide, a strong safety culture among members, and the presence of union stewards who monitor compliance. Many non-union contractors also maintain excellent safety records through strong internal programs.

Q3: Can a construction company use both union and non-union labour on the same project?

A: This is complex and depends heavily on contractual agreements and project types. A general contractor might be a union on some projects, especially public works. Still, some subcontractors might be non-union (this is known as “mixed shop” or “open shop” depending on the project type and location). However, strict rules and potential jurisdictional disputes often arise when mixing union and non-union workers on the same scope of work or even on the same site. It requires careful planning and legal consultation.

Q4: How do unions ensure the quality of their workforce?

A: Unions ensure the quality of their workforce primarily through rigorous, multi-year apprenticeship programs that combine extensive on-the-job training with classroom instruction. They also provide continuous journeyman training to update members on the latest techniques, technologies, and safety standards. This structured approach aims to produce highly skilled, certified, and consistent craftspeople across trades.

Q5: What is a “collective bargaining agreement” (CBA) in construction?

A: A collective bargaining agreement (CBA) is a legally binding contract between a labour union and an employer (or group of employers) that governs the terms and conditions of employment for union members. In construction projects, a CBA typically defines specific wage rates, fringe benefits (health, pension, training), working hours, overtime rules, grievance procedures, and hiring practices for unionized workers on the project. It aims to standardize labour relations and provide stability.