Introduction: Why Construction Cost Estimation Matters More Than Ever

Every project’s success relies largely on having accurate estimates for construction costs. Creating a solid financial projection is essential whether you’re building a housing project, a business office, or a technology center. As we approach 2025, the construction sector is affected by unstable supply chains, rising global inflation, sustainability rules, and quickly developing technology. If project managers don’t estimate costs properly, the project can be delayed, become involved in legal problems, and run out of money. Why do costs often change from one location to another? We explain the five most significant factors, backed up by real examples from Fusion Assist, a leading provider of remote construction estimating services. Furthermore, we’ll discuss the trends, technology, and tools changing estimation.

Factor 1: Project Scope and Design Definition

Project Scope is the starting point of any estimate, and if handled poorly, it is the No. 1 cause of cost deviation. If the plan is unclear or often changes, your budget is likely to become unstable.

What Does “Scope” Include?

- The type and size of the project

- Performance specifications

- Choices of materials and their finishes

- Mechanical, electrical, and plumbing (MEP) systems

- Design alternatives

- Inclusions/exclusions

- Change order procedure

The Dangers of Scope Creep

Changing something small, like the tiles or adding a balcony, may seem harmless, but it may add a huge amount to the budget. Industry reports indicate that scope creep leads to around 30-50% of all extra costs in construction projects worldwide.

Fusion Assist Case Study – Healthcare Facility, Melbourne

During the early stage of building a 220-bed hospital expansion, Fusion Assist kept track of changes in the BIM model as they happened. Nearly 100 different changes were made to the design before it was put out for tender. Early identification of these trades reduced the risk of change-order claims by $3.2M, making the project more cost- and time-efficient.

Factor 2: Market Conditions – Materials & Labor Volatility

Rates for concrete, steel, timber, and copper fluctuate weekly in many global markets. Finding enough workers makes this even more difficult.

Material Inflation in 2025

- Steel prices rose 18% YoY (Source: World Steel Association)

- Timber is becoming scarce because of problems with global shipping.

- Now, carbon-reducing chemicals are added to the mix, adding to the overall cost.

To get reliable quotes from vendors, smart estimators look for at least three choices per material and include a 5–10% cost increase buffer in long project estimates.

Labor Dynamics

Due to a lack of skilled trades, wages have increased, mainly in North America and Western Europe. Having a union covers workers, but it also means higher costs and compliance expenses.

Fusion Assist Case Study – Solar Project, Arizona

With both panel costs and labor being scarce, Fusion Assist created several cost models using different suppliers and worker rates. By switching to a different route for logistics, the company managed to cut freight charges by 12% which made the project financially attractive for tax-equity investors.

Factor 3: Site Conditions and Project Location

Site-specific variables can make or break a project budget, even if the design is consistent.

Factors That Impact Site Costs

- Soil type and geotechnical risks

- Topography (slope, drainage)

- Access roads and logistics constraints

- Weather patterns and seasonal impacts

- Proximity to utilities and services

- Local zoning and environmental regulations

Urban vs. Rural Construction Costs

Urban projects tend to have:

- Higher labor costs

- Restricted access (crane, storage, deliveries)

- Strict noise, dust, and work-hour regulations

Rural builds face longer travel times and fewer subcontractor options.

Fusion Assist Case Study – High-Rise Tower, Toronto

Fusion Assist’s team modeled over 20 site-specific risk scenarios using GIS overlays and geotechnical data. This predictive model uncovered high groundwater levels, leading to pre-approved contingencies for water treatment and dewatering systems. Result: zero delay and no budget deviation.

Factor 4: Project Timeline and Scheduling

Delays = dollars. The longer your project runs, the more you spend on general conditions, labor escalation, and loan interest.

Why Schedule Matters in Estimation

Every estimator should analyze:

- Construction start date

- Seasonal impacts (rain, snow, heat)

- Number of shifts

- Float time in the critical path

- Long-lead items and procurement risk

Even minor errors in scheduling assumptions can derail estimation accuracy.

Lean Construction and Productivity Tools

Modern estimation isn’t just about cost—it includes productivity analysis. Lean scheduling techniques include:

- Pull Planning

- Just-In-Time Material Delivery

- Daily Crew Targeting is now integrated into Procore, PlanGrid, and Oracle Primavera tools.

Fusion Assist Case Study – Logistics Center, UAE

Using lean construction models, Fusion Assist predicted a 14-day productivity gain through phased slab pours and modular MEP installations. This saved $480,000 in site management and reduced idle crew hours by 22%.

Factor 5: Contract Type, Risk Allocation & Contingencies

Different contract structures create different cost expectations. The estimator must factor in who carries what risk.

Common Construction Contracts and Their Impact

- Lump-Sum: Contractor carries more risk → higher markup

- Cost-Plus: Owner carries risk → needs larger contingency

- GMP (Guaranteed Max Price): Hybrid with shared risk and strict cost control

- IPD (Integrated Project Delivery): Collaborative with pooled contingency

How to Allocate Contingency Wisely

Typical contingency reserves:

- 5–7% for design maturity above 90%

- 10–15% for early-phase or complex projects

- Separate reserve for client-driven design upgrades

Fusion Assist Case Study – Data Center Campus, Germany

Energy costs were expected to spike due to regional tariffs. Fusion Assist modeled a multi-tier contingency based on projected utility price brackets. This foresight allowed the contractor to hedge risks using fixed-term power purchase agreements.

Emerging Trends in Construction Estimation for 2025 and Beyond

As the construction industry evolves, so do estimation practices. The projects’ growing complexity, demand for sustainability, and reliance on data reshape how professionals approach costing.

1. Sustainability-Driven Estimating

Clients increasingly prioritize green materials, low-carbon construction methods, and energy-efficient systems.

Cost Impacts of Green Building:

- LEED or BREEAM certification can add 5–15% to the base cost.

- Renewable materials (e.g., bamboo, recycled steel) are often more expensive but reduce lifecycle costs.

- Many public projects now require environmental impact modeling as part of the estimate.

2. Digital Twins and BIM-5D Integration

Modern estimators are now using 5D BIM, which integrates time and cost dimensions into a digital twin of the structure.

Benefits include:

- Real-time material quantity takeoffs

- Clash detection and cost forecasting

- Scenario testing for design alternatives

Fusion Assist has reported a 38% faster estimation cycle using integrated BIM pipelines.

3. Estimating for Resilience and Climate Risk

As weather events grow more extreme, risk-adjusted cost planning is becoming standard. This includes:

- Flood and wildfire mitigation strategies

- Seismic construction adjustments

- Wind-load design premiums

- Insurance escalators for at-risk zones

The Role of AI and Automation in Cost Estimation

AI is transforming traditional workflows in construction estimation, making processes faster, smarter, and more accurate.

Key Benefits of AI-Powered Estimation

- Automated quantity takeoff from 2D plans or 3D models

- Historical data mining for better forecasting

- Cost variance alerts for out-of-range figures

- Machine learning models that suggest more cost-effective alternatives

Fusion Assist is currently piloting AI models that suggest optimal suppliers based on cost history, delivery time, and carbon footprint, cutting vendor selection time by 60%.

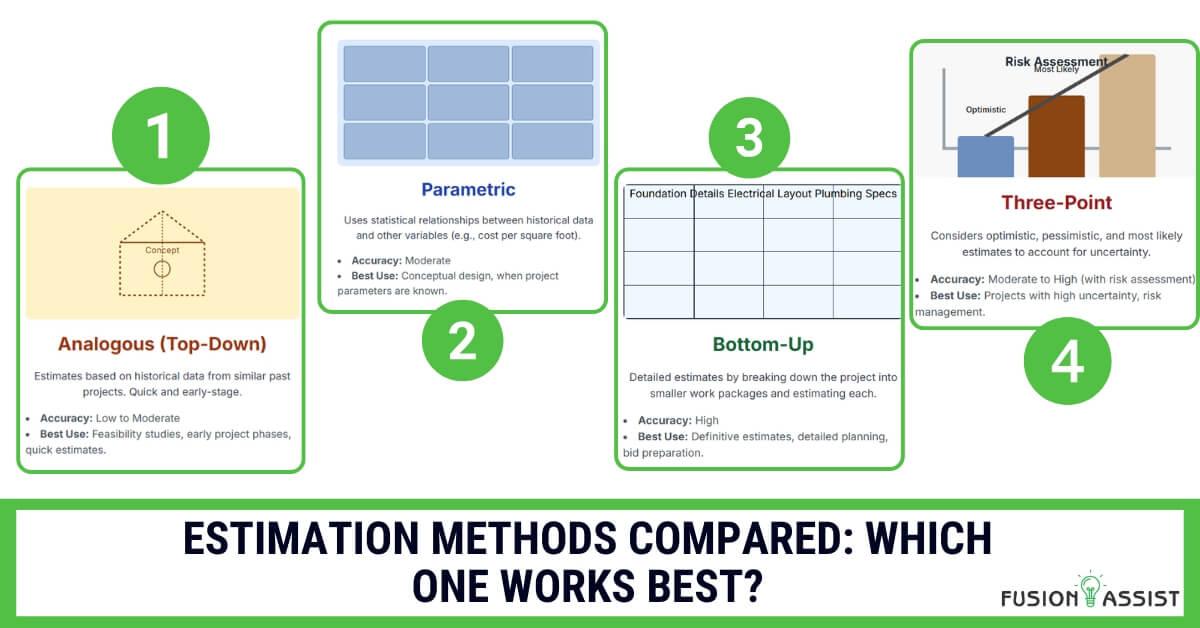

Estimation Methods Compared: Which One Works Best?

Different methods suit different project phases and complexity levels. Here’s a breakdown:

| Estimation Method | Best For | Accuracy | When to Use |

|---|---|---|---|

| Analogous (Top-Down) | Early concept design | ±25–40% | Feasibility & budgeting |

| Parametric Estimating | Modular buildings, repeatable units | ±15–25% | Budget alignment |

| Bottom-Up Estimating | Detailed design with full specs | ±5–10% | Tendering & bidding phase |

| Three-Point Estimating | Risk-heavy, unique projects | Variable | Contingency planning |

Fusion Assist often uses hybrid methods—combining bottom-up for MEP systems and parametric estimating for civil works—to optimize speed and accuracy.

Sector-Specific Estimation Considerations

1. Residential Construction

- More affected by local labor availability

- Estimation often includes allowance for finishes (tiles, fittings)

- Needs high flexibility for owner-driven changes

2. Commercial Projects

- Involves more mechanical and electrical systems

- Requires fire, safety, and accessibility compliance

- Time-to-market heavily influences indirect costs

3. Infrastructure & Public Works

- Must comply with public procurement rules

- Heavily affected by site logistics and environmental impact

- Contingency planning must account for community risks and delays

Fusion Assist Case Study: Mixed-Use Development, London

A leading developer in London approached Fusion Assist for a 3-tower, mixed-use project comprising 420 residential units, retail outlets, and underground parking.

Challenges Faced

- Volatile steel and concrete prices

- Local council requirements for green energy

- Tight schedule due to phased occupancy

Fusion Assist’s Solutions

- Created a multi-scenario estimate to factor price inflation across 18 months

- Integrated real-time supplier pricing via APIs

- Added a carbon-cost overlay for sustainability mandates

- Built a modular costing model that enabled developers to lock in long-lead items early

Results

- The project stayed within 2.6% of the final budget

- Gained LEED Gold compliance

- Avoided $1.1M in delay penalties due to optimized scheduling

Conclusion: Build Smarter with Accurate Estimation

Construction cost estimation isn’t just math—it’s a strategic function that decides whether your project thrives or stalls. You can confidently control costs by mastering scope clarity, market volatility, site complexity, time management, and contract strategy.

Fusion Assist empowers developers, architects, and contractors with cutting-edge, AI-assisted estimating services that mitigate risk, increase precision, and save time.

Ready to reduce uncertainty in your next build?

Contact Fusion Assist for a customized cost estimation plan and discover how technology can unlock your project’s full potential.

Frequently Asked Questions (FAQs)

1. What are the five key factors in construction cost estimation?

The top five are scope definition, market conditions (materials and labor), site/location, scheduling, and risk allocation.

2. What tools do professionals use for cost estimation?

BIM tools like Revit and Navisworks, cost software like CostX, Bluebeam, and AI platforms like Togal.AI and ALICE Technologies.

3. How much contingency should be added to a construction estimate?

Typical ranges are 5–15%, depending on project complexity, phase, and contract type.

4. Is AI reliable for estimating costs?

AI enhances traditional estimation by speeding up takeoffs, identifying anomalies, and optimizing cost-performance balance, but human review is still essential.

5. Can I outsource construction cost estimation?

Yes, remote firms like Fusion Assist offer expert estimators who provide fast, accurate, and tech-enabled services across global markets.